Product brand: Zhihao

Product application:

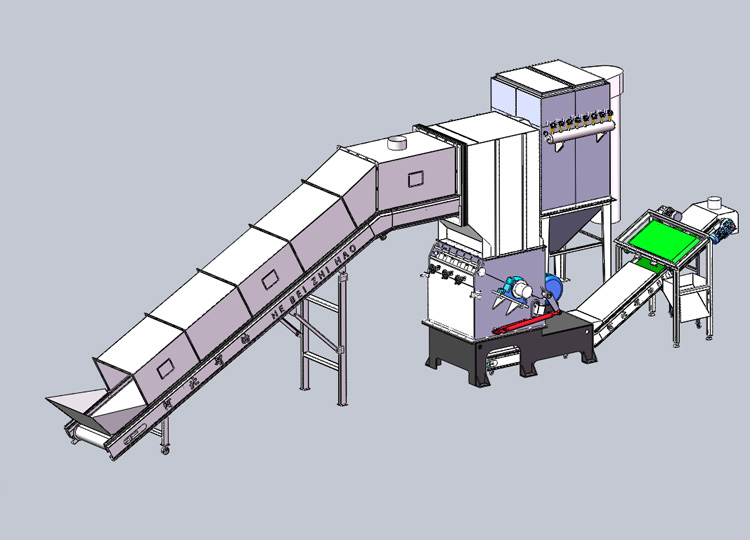

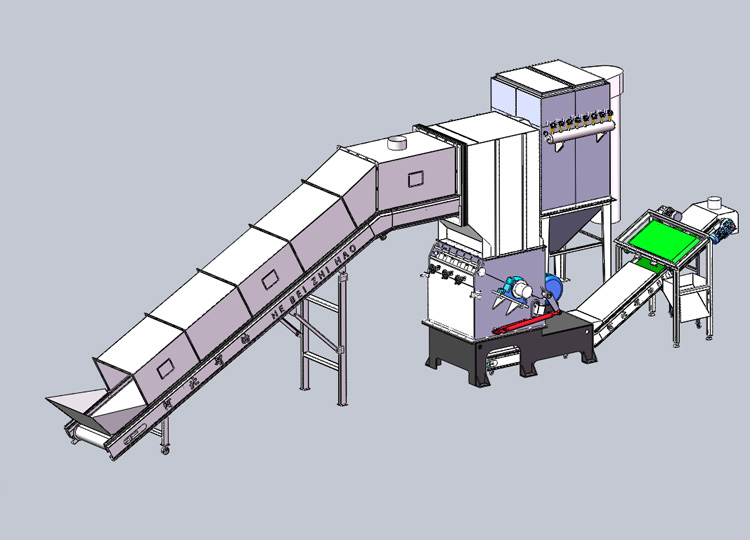

ABS and PS household appliance shell crushers are mainly used to deal with the dismantling and crushing of large and hollow household appliance shells such as washing machine shells, TV shells, refrigerator shells, computer shells, air conditioning shells, automobile battery shells, electric vehicle battery shells and so on.

Product introduction:

The home appliance crusher is an intelligent, efficient and environmental friendly crusher. The home appliance crusher is different from the ordinary crusher mainly in the variety, strength and complex volume shape of hard plastics. Therefore, the crusher needs greater resistance and a suitable caliber.

ABS and PS household appliance shell crushers are mainly used to deal with the dismantling and crushing of large and hollow household appliance shells such as washing machine shells, TV shells, refrigerator shells, computer shells, air conditioning shells, automobile battery shells, electric vehicle battery shells and so on. A little carelessness in the recycling process of waste plastics may cause serious pollution to the environment. If it is not effectively treated, it will bring great harm to the environment.

The crusher drives the moving cutter head to rotate at a high speed through the motor. During the high-speed rotation of the moving cutter, it tends to form a relative movement with the fixed cutter. The gap formed between the moving cutter and the fixed cutter creates a cut for plastic crushing and shearing, so as to crush large pieces of plastic. The crushed plastic is filtered through the screen to output the plastic particle size.

Product advantages:

① equipped with automatic conveyor feeding device to reduce labor force and improve production efficiency

② anti jam, anti slip and anti deviation protection for feeding and conveying, height adjustable

③ sealing device is used for feeding and conveying to prevent material leakage, and soft connection is used for sealing with the crusher inlet. The sealing effect is better, which can prevent materials from flying out during crushing and avoid personal injury

④ crusher is dedicated to hard material crusher. It adopts wear-resistant design and weighted structure to ensure long-term continuous and stable operation of the system, and the tool will not overheat molten material

⑤ it is made of high-quality carbon steel by professional registered welders, which is welded firmly and polished smoothly.

⑥ the processed and broken pieces are uniform and have little loss. The screen can be changed according to the crushing demand.

⑦ it is fastened with high-strength screws, with solid structure and durability.

⑧ the outlet is equipped with an automatic conveying device, which is well connected with the crusher without leakage.

⑨ the conveying end is equipped with a magnetic separation conveyor belt, which can effectively remove metal from plastic.

⑨ the crushing equipment is equipped with dust removal facilities, and in a closed space, the on-line treatment of dust during crushing can be realized to reduce dust emission and protect the environment.

technical parameters:

|

Size of feeding conveyor belt

|

7210*970*3750mm

|

|

Power of feeding conveyor

|

2.2kw

|

|

Feeding and conveying function

|

≥2t/h

|

|

speed

|

5-10m/min(Adjustable)

|

|

Belt specification

|

thickness10mm

|

|

Crusher model

|

ZHHB-PSJ-1200D

|

|

Crusher size

|

2552*2174*4138mm

|

|

capacity

|

≥2t/h

|

|

Motor power

|

55kw

|

|

Feeding port

|

1200*1000mm

|

|

Spindle speed

|

760turn/min

|

|

Tool material

|

DC-53(≥200One sharpening per ton)

|

|

Number of tools

|

4 fixed knives and 6 movable knives

|

|

Discharge conveyor size

|

5356-820*1950mm

|

|

Output conveyor power

|

2.2kw

|

|

Discharge conveying capacity

|

≥2t/h

|

|

speed

|

0-15m/min(Adjustable)

|

|

Belt specification

|

thickness10mm

|

|

Magnetic separator efficiency Iron removal rate

|

99.5%

|

|

Magnetic separator power

|

1.5kw

|

|

Belt specification

|

Width 800mm, thickness 10mm

|

|

Magnetic plate

|

800*600*150mm

|

|

Random dust collector, power

|

64 filter bags, power 7.5kw

|

Renewable Resource Equipment

Renewable Resource Equipment